June 13, 2022

Blog

Components of plastic bearings

Components of plastic bearings

Plastic bearings do not have the high-pitched, rolling noise of metal, also those are easy to use. Those are ideal for applications where metal bearings would be of excessive quality. Currently, TOK has a lot of plastic bearings that are easy to install and competitive price, There are so many different types, so you may not know which one to use. In this issue, we will introduce the characteristics of each part as well as the component structure of plastic bearings so that you can select the most suitable plastic bearing for your application.

Components of plastic bearings

Components of plastic bearings

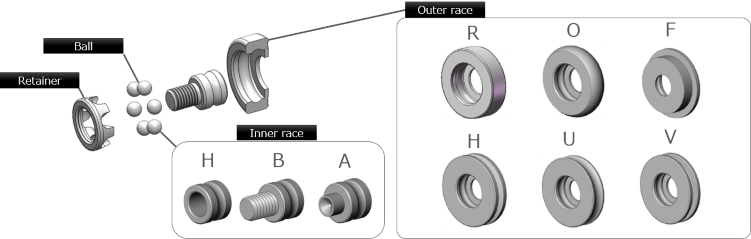

Our plastic bearings consist of outer races, inner races, balls, and retainers.

We have six types of plastic outer races and three types of inner races. Inner laces are available to choose how to attach to mating parts. These can be flexibly combined according to customer requirements. For example, when you use on a desk drawer, we recommend a combination of a flat outer race (R in the figure) and a screw-type (B in the figure) inner race. It can be easily assembled to the drawer with screws, also it allows the flat rail to run smoothly.

Plastic bearing outer race types

Plastic bearing outer race types

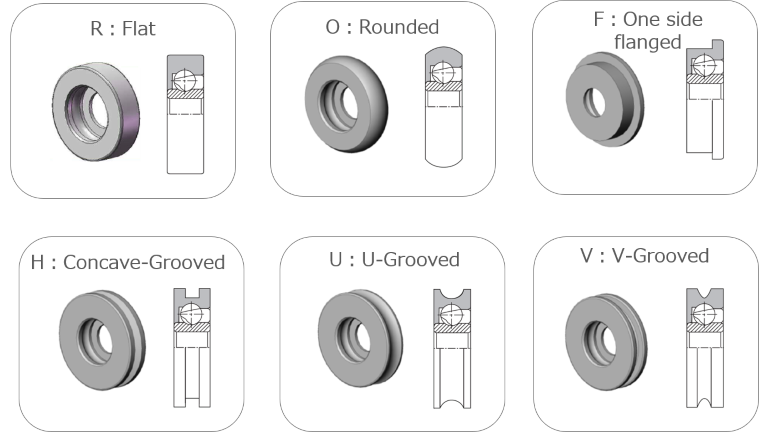

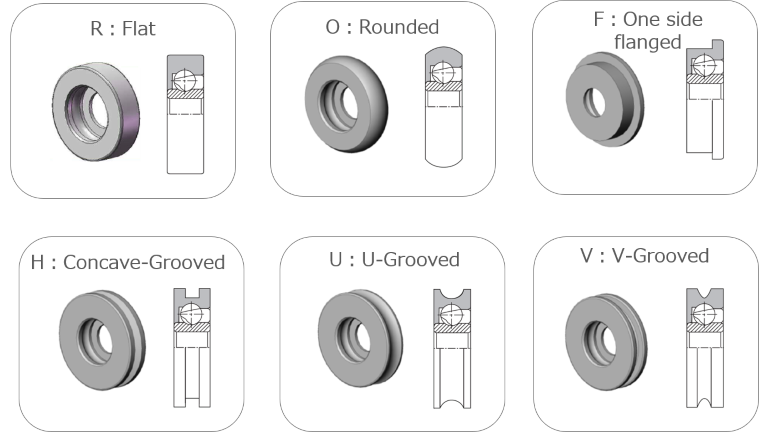

We have Flat type, convex type, flange type, concave type, u-groove type and v-groove type outer races. Plastics can be easily molded by injection molding, so many types can be made.

The main applications for each shape are as follows;

R: Flat outer circumference, used in a wide range of industries. Mainly used for office desks and refrigerator drawers.

O: Outer circumference convex R shape. Often used as a bearing running on rails with concave R shape, which makes it relatively difficult for the wheel to come off the rail. When running on a flat surface, the contact surface becomes a point contact, which is useful for suppressing running noise when the mating material is made of aluminum, which is prone to resonance.

F: Flanged shape. When bearings are used on both sides of a drawer, one side of the bearing is flanged. This will prevent rattling and maintain smooth movement when pulling out the drawer. In factory and distribution equipment-related applications, it is sometimes used to insert on both sides of pipes of conveyor rollers to prevent them from entering the pipes with flanges.

H: Outer circumference concave groove shape. Works well with convex rails such as curtain rails and screen doors.

U: Outer circumference U-groove shape. This product is widely used as a door roller for hanging doors, such as storage rooms and closets.

V: Outer circumference V-groove shape. Many of them are used as wire pulleys.

Plastic bearing inner race types

Plastic bearing inner race types

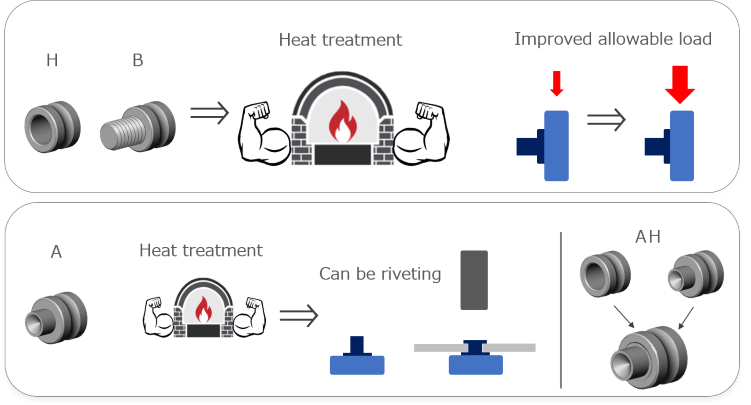

We have three types of inner races: hole type, screw type, and rivet type.

The hole type (H in the figure) is the same mounting method as for metal bearings. This is best for use through the shaft, but when preparing a separate part and attaching it to the mating part, it is easier to use the caulking shape (A in the figure) or the screw shape (B in the figure).

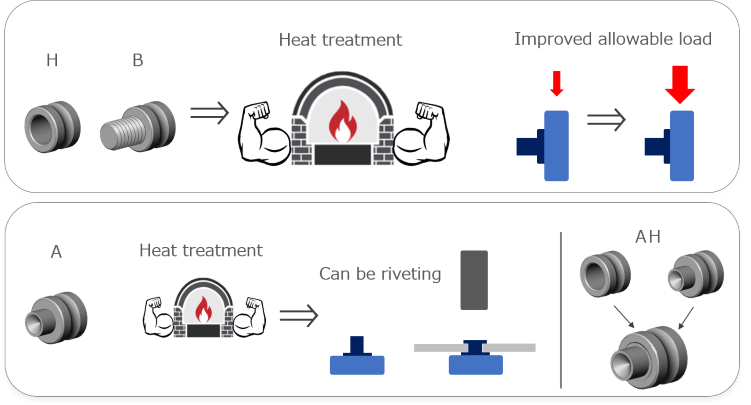

Plastic bearings with rivet inner races can be easily installed by inserting the shaft portion of the inner race into a hole in a pressed part or sheet metal and crushing the shaft portion with a riveting machine. However, since the shaft part cannot be quenched (surface hardening treatment) in order to crush it, we recommend using hole or screw type if you want to increase the allowable load. If you want to attach the shaft by riveting, we also have a type (AH in the figure) with the shaft pre-installed in the hole shape.

We basically use metal ball. Carbon steel balls which are heat-treated or stainless-steel balls are the most common, but if chemical resistance is more important than load capacity, glass or plastic balls are also another option.

Retainers are mainly used injection molded polypropylene.

Our retainers are available in 10 different sizes and are used according to bearing size. Polypropylene has good chemical resistance and self-lubricating, so it can maintain a certain level of durability without the use of grease in the bearing. (Our plastic bearings are basically filled with grease.)

Conclusion

Conclusion

Plastic generally gives us the impression of weaker than metal. Nowadays, there are various types of plastic, and some of them are not inferior to metal in strength. However, the strength of commonly plastic is about 1/6 to 1/8 that of metal. Although there are concerns about the strength of plastic, our plastic bearings are designed to fully demonstrate the characteristics of plastic. The light specific gravity, self-lubricating properties, and the ability of plastic to be easily molded into various shapes are advantages not found in metal. If you use plastic bearings, you will understand that they are easier to use than metal bearings.

We have introduced our standard product lineup as the basis for this article, but custom designs are also available if the quantities are large enough. If you cannot find your desired specifications, please feel free to contact us.